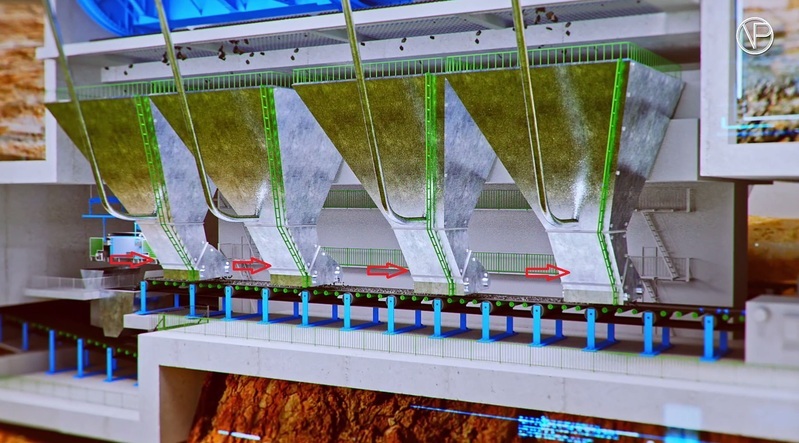

Vostochny Port, operator of Russia’s largest dedicated coal port, says it has increased the efficiency of railcar unloading having upgraded its coal hoppers of the tandem-type railcar dumper facility No3.

According to the statement, the innovation of changing the angle of slope of the hopper’s backwall from 45 to 60 degrees (in order to increase the area of passage and prevent sticking of coal to the hopper walls) was the idea of Aleksandr Astashkin, team engineer of the coal terminal’s Phase 3 railcar dumper, who developed the improvement and introduced it into the production process together with his colleagues.

In the end of 2020, Vostochny Port specialists changed the design of a coal hopper and then monitored the pilot operation of the railcar dumper facility No3. The findings confirmed almost no non-productive time needed for cleaning of the hopper which used to take up to 12 hours per day before modernization. The coal was easily falling onto underground conveyors. Having confirmed the expected results of the modernization the company decided to upgrade the entire axle of four hoppers at the railcar dumper facility No3. The next will be the four hoppers of the railcar dumper facility No4 with the works to begin in June 2020.

Each complex of four closed hopper facilities can simultaneously handle eight railcars. It takes 2.5 minutes to take over 600 tonnes of coal. Dry fog and aspiration system within the closed facilities mitigate the environmental impact of the coal handling process.

“Two modern closed railcar dumper facilities of the Vostochny Port’s coal terminal can unload over 2,000 open railcars per day, - says Vadim Baibak, Managing Director of the company. – High railcar handling rate ensures optimization of the entire process of transportation by Russian Railways and ensures higher sales of coal to consumers in the APR countries as part of Russia’s total exports”.

Vostochny Port JSC (Vrangel settlement, Primorsky Region) is Russia’s largest specialized terminal with high-tech coal handling. Vostochny Port is a free access facility open for all coal manufacturers of Russia. In 2020, it handled 26.85 million tonnes of cargo.

The terminal features covered stations for unloading and transfer of coal, conveyor equipment, rotary car dumpers, shiploaders and the second-to-none system of multi-stage magnetic coal separation.

Vostochny Port is the first coal port in the Far East that obtained a certificate of compliance with ISO 14001:2015 “Environmental Management System: Requirements and Application Guide.” The certificate confirms the company’s compliance with both Russian and international requirements on environmental risk management. The key element of the company’s environment protection is the system of dust and wind protection facilities of more than 20 metes high and about 3 kilometers long. As of today, they are the largest protection facilities in the Far East.

Phase 3 of Vostochny Port’s coal terminal put into operation in early September 2019 is the most ambitious private investment project costing over RUB 40 billion and implemented through public private partnership without involving state financing. Phase 3 lets the terminal increase its annual throughput to 50-55 million tonnes. The Phase 3 project has generated more than 600 new high skill jobs. By 2026, the project will ensure a total of RUB 25 billion of tax payments that will give a powerful impetus to the social and economic development of the Primorsky Territory.

Photos provided by Vostochny Port’s press center