The 260-foot vessel will be built for Edison Chouest Offshore (ECO) by North American Shipbuilding

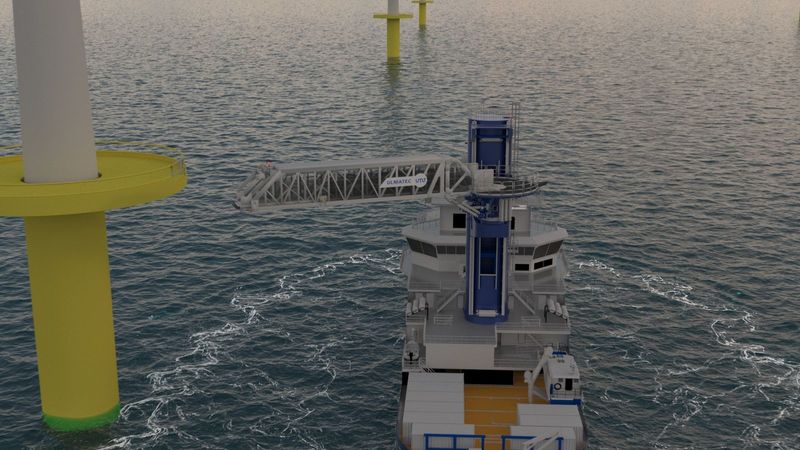

ULMATEC has secured a contract for the supply of a 32-meter motion compensated gangway and logistics support systems for the next US-built Jones Act service operation vessel.

This 260-foot vessel will be built for Edison Chouest Offshore (ECO) by North American Shipbuilding, an ECO affiliate. The vessel is sister design to the “ECO Edison” and will feature spacious cabins and well-appointed facilities for 60 technicians. The vessel will be energy efficient and has been designed with a high level of comfort in mind.

The hybrid drive gangway offers superior energy consumption numbers compared with all-electric gangways. With the accumulator-stabilized boom, energy consumption for lifting and luffing is minimized. The workability of the vessel is supported by the gangway’s 12m telescope compensation range, infinitely adjustable access height (to the wind turbines) and integrated elevator in the gangway pedestal

Logistics is supported with electric drive trolleys along the stepless gangway, and loading and unloading of the vessel will be completed with an integrated 6 metric ton crane function. For offshore use, a fully 3-D compensated, 3 metric ton crane will be accessible via the underside of the gangway.

“It is a sign of confidence from Edison Chouest Offshore that they again choose our gangway. Our development in cooperation with the shipowner and yard ensures a perfect fit for the vessel. Parts of the gangway delivery is in fact manufactured by the yard, ensuring good integration, less energy consumption through local manufacture and lots of timing flexibility for the yard. Our gangway system is fully DP integrated, assisting the crew in choosing the right access point and route between the wind turbines” says Bjørn Gjerde - Sales Manager in Ulmatec

Chief Commercial Officer Bjørnar Huse adds: “Our third gangway overall and second gangway to this customer shows that our systems are a good fit for the task. Combined with our other deliverables, this will be another highly capable vessel. Our mooring winches, boatlandings, cargo handling systems and heat recovery solutions combine to make full scope delivery for SOVs. With this second delivery starting its charter in 2025 our service organization can fully support the US market with remote assistance from our engineers in Norway. We are looking into the best location for a US hub for gangway service and spare parts.”

“Ulmatec has successfully developed the gangway and W2W system. Our engineers continually improves and refines the system performance, focusing on weight and workability. The manufacture will be done locally in Norway and by the yard in the US. This ensures full control of the finished product and no emissions for moving large units from remote locations for testing. With the increased activity in both W2W system deliveries as well as seismic equipment and subsea LARS systems we are looking to expand our local manufacturing workforce and facilities.” says Chief Executive Officer Iver Bjørnerem

“Ulmatec has shown to be a dependable and flexible vendor for complex handling systems, as well as offering routine maintenance and problem solving on short notice for ECO companies over many years. We look forward to having the gangway deliveries to the same standard”, says ECO CEO Gary Chouest

Ulmatec Handling Systems is part of the Ulmatec group, a multinational corporation that offers handling equipment, In-sea seismic equipment under the Baro brand, and heat recovery solutions under the Pyro brand. Service and support organizations at three sites in Norway plus USA.